WHO ARE WE?

Spring Science Specialists

Atlas Microtech, founded in 2006, is a manufacturing company specializing in the production of springs, located in Porrentruy, in the Jura region, at the heart of the watchmaking industry. In partnership with Metalab, a renowned laboratory known for its expertise in material study and characterization, we have expanded our activities to include the manufacturing of spiral springs and barrel springs. These components play a strategic role in the mechanism of mechanical watches.

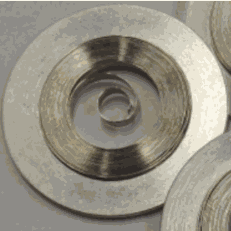

barrel springs

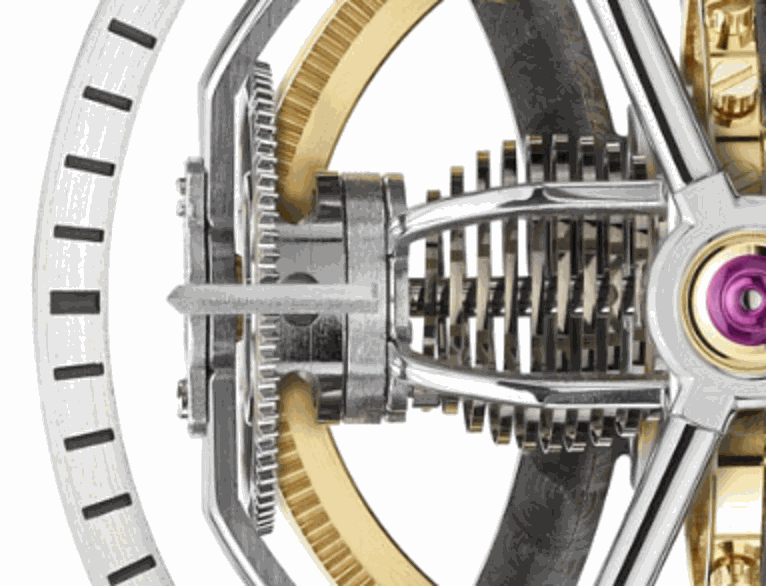

The mainspring is the centerpiece of the watch movement, storing and releasing the energy of the mechanical watch. At Atlas Microtech, we provide high-precision manufacturing to ensure performance and reliability.

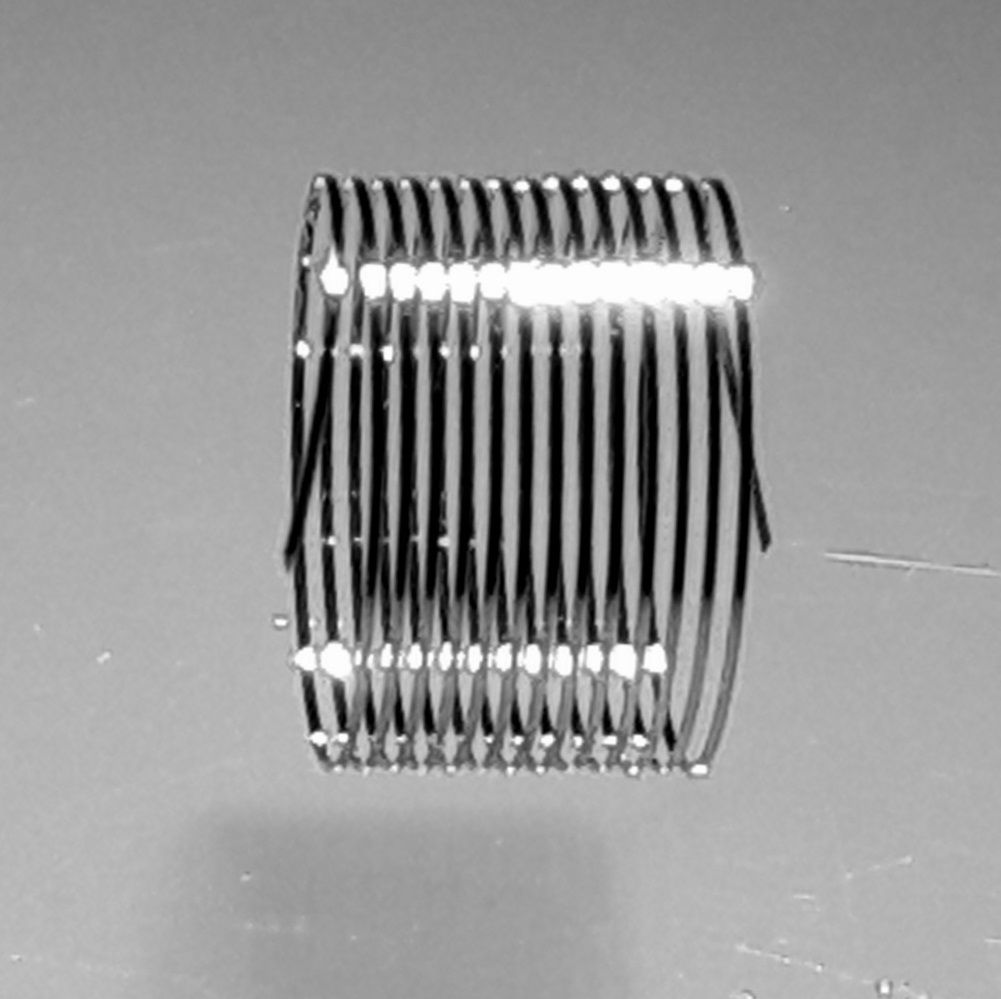

flat springs

A key element in the regulation of a watch, the flat balance spring plays an essential role in the precision of the movement. Our balance springs, tested and chronometer-certified (COSC), offer an optimal thermo-elastic constant (CTE). Thanks to our mastery of the manufacturing process, we guarantee perfect reproducibility of each part.

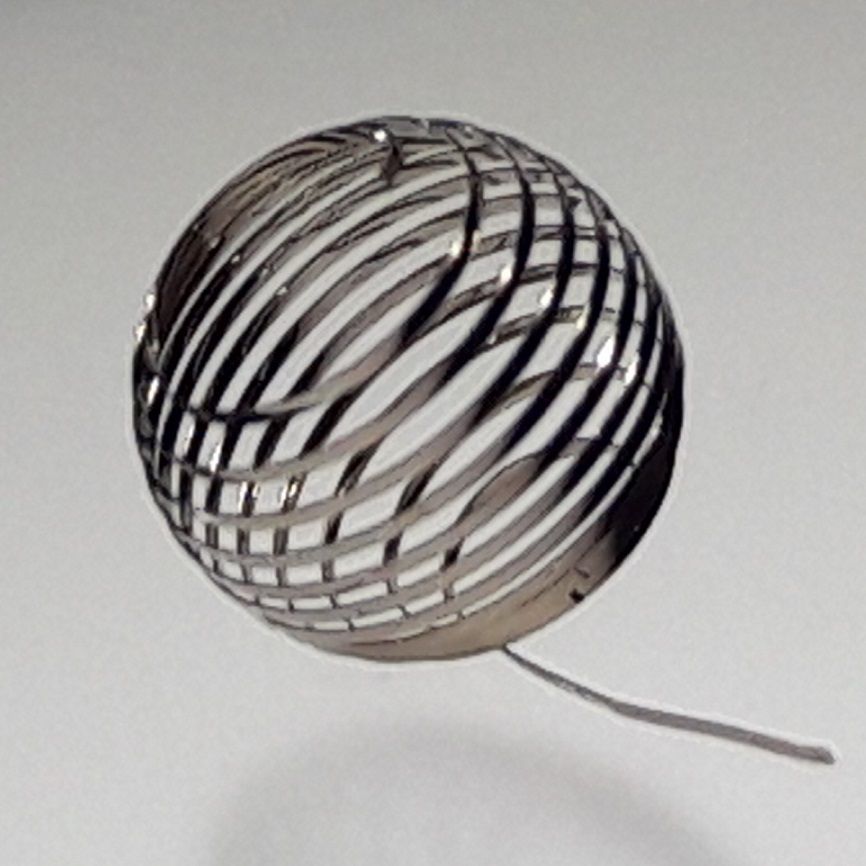

SHAPED Srings

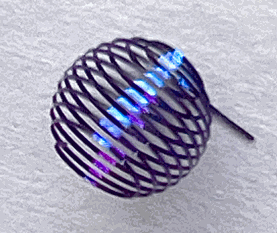

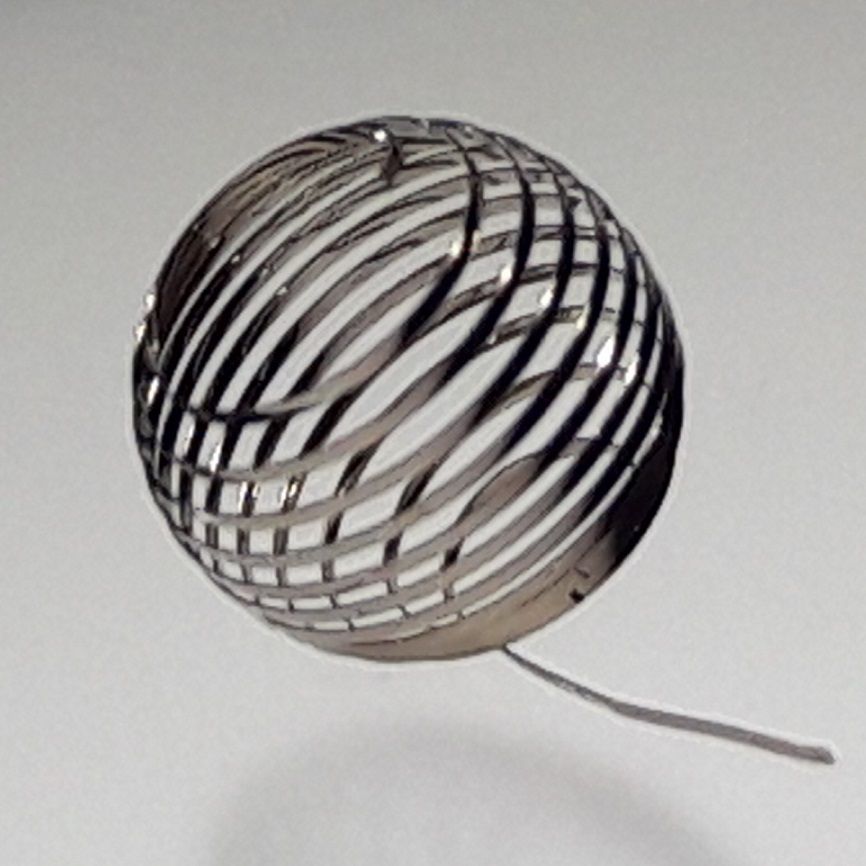

Spherical and cylindrical balance springs provide improved performance in terms of isochronism and aesthetics. Tested and certified chronometers (COSC), they have an optimal thermo-elastic constant (CTE). Our manufacturing process guarantees perfect reproducibility, ensuring identical mechanical and dimensional characteristics for each part.

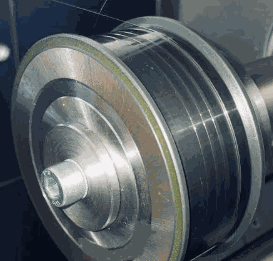

Coil of drawn wire Shelled springs

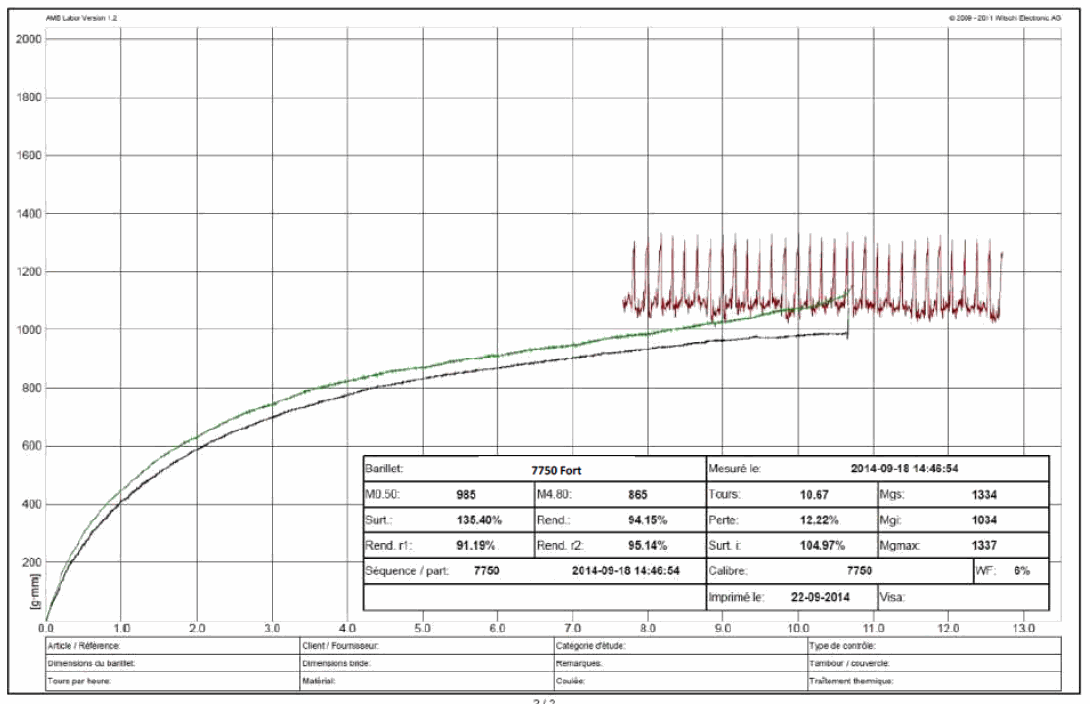

All barrel springs manufactured at Atlas Microtech undergo rigorous quality control, including verification of cleanliness, uniformity, thickness and height of the spring. These requirements allow us to ensure optimal performance and impeccable reliability.

We also conduct extensive performance tests, such as fatigue testing, to ensure the durability and effectiveness of our springs. Thanks to this meticulous work and our know-how, we now supply the greatest Swiss watchmaking houses.

For any request relating to mainsprings, please complete the form below:

form

Winding and disarming curve of an automatic mainspring.

We master every step of the flat spring manufacturing process, from tool design to final production. Thanks to our expertise in drawing, rolling, and manufacturing, we guarantee high-precision products tailored to the requirements of watchmaking and other technical applications.

Here are the different stages of our manufacturing process:

Finally, we master the manufacturing of several types of shaped springs, including spherical and cylindrical springs as shown below. As with our other springs, we carry out the entire manufacturing process in-house, from drawing and rolling to final production. We work with our own alloy, Nivarox, as well as alloys developed according to our clients' specifications, ensuring performance that meets the strictest requirements.

This complete mastery allows us to guarantee impeccable quality and perfect repeatability: each shaped spring exhibits the same mechanical and dimensional characteristics, regardless of the quantity produced.

We also offer a coloring option for the springs. Spherical and cylindrical springs can be tinted in various shades, such as purple or golden yellow, without altering their physical and mechanical properties. This customization combines aesthetics and performance to meet the demands of the most refined timepieces. Here are some examples of colorations we can achieve for a spherical spring:

GOLD blue PURPLE

For any request relating to the flat springs, please fill in the contcat form contact contact form

Innovation is at the heart of our know-how. We conduct research and development projects to optimize the performance of our springs and explore new technical solutions. Thanks to our expertise in materials and manufacturing processes, we design ever more high-performance balance springs and mainsprings, adapted to the most demanding requirements of watchmaking.

To reduce the magnetic sensitivity of nickel-based alloys and strengthen their impact resistance, we are developing new paramagnetic alloys. These advances improve the performance and reliability of high-precision watch components.